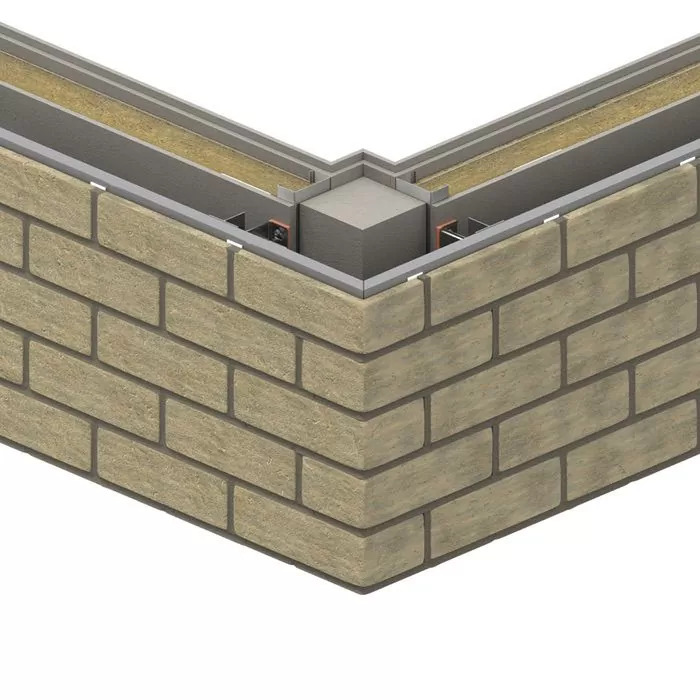

Mechslip Brick Cladding

Nationwide supplierResponding to the evolving demands of the construction market, MechSlip offers architects and specifiers the opportunity to incorporate authentic brick with the versatility of a fully mechanically fixed cladding system. Unlike purpose-made extruded brick slips, MechSlip provides a broader range of design options by combining over 300 Ibstock brick finishes with the adaptability and cost efficiency of a flexible and robust cladding support system. Our claim is clear: MechSlip delivers a superior brick cladding solution without compromising quality. By using MechSlip bricks, architects and specifiers can maintain the integrity of their designs. At the same time, the Axial mechanical fixed system opens a world of possibilities for integration with modern construction methods.

Efficiency and Durability Combined

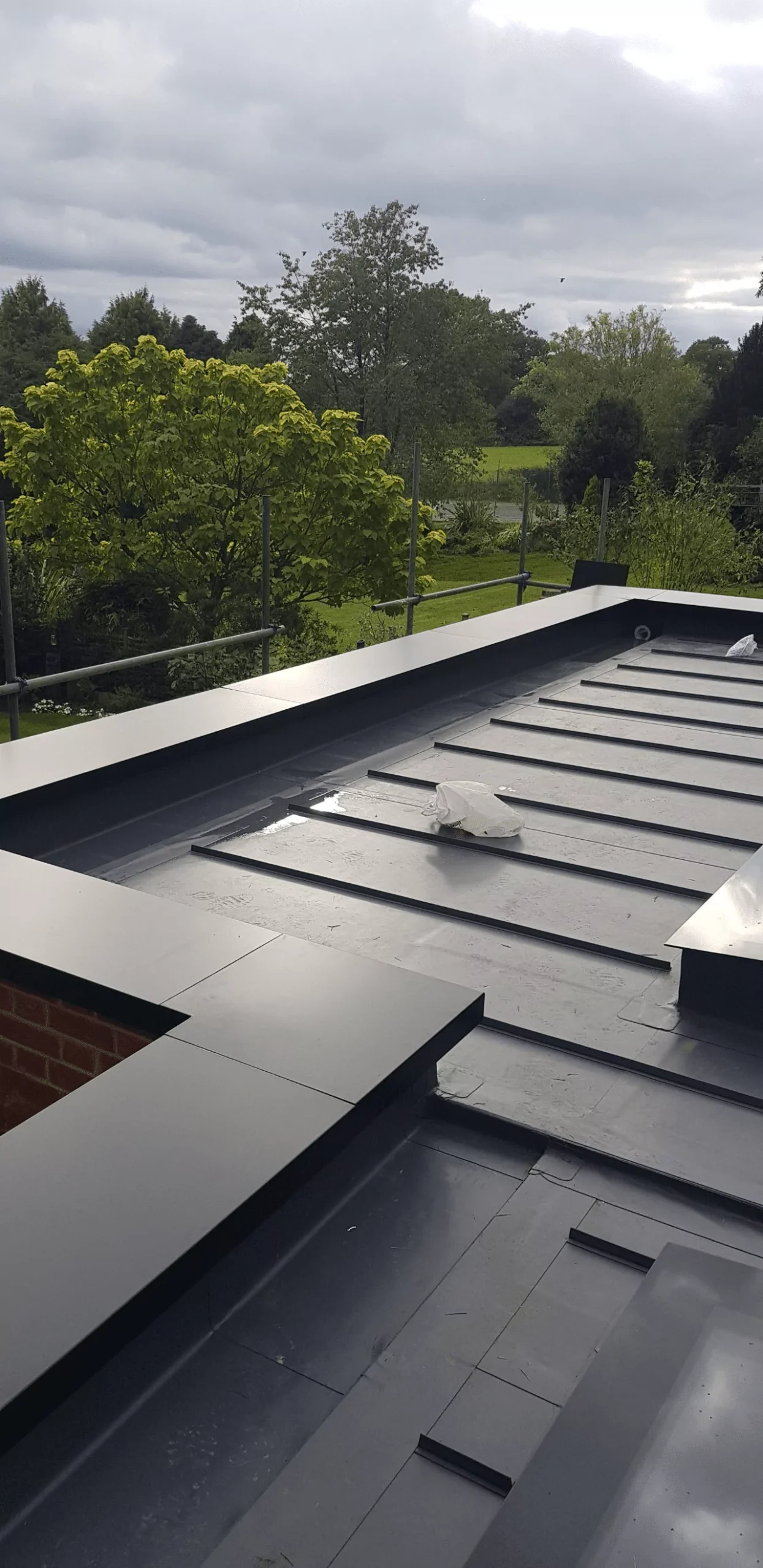

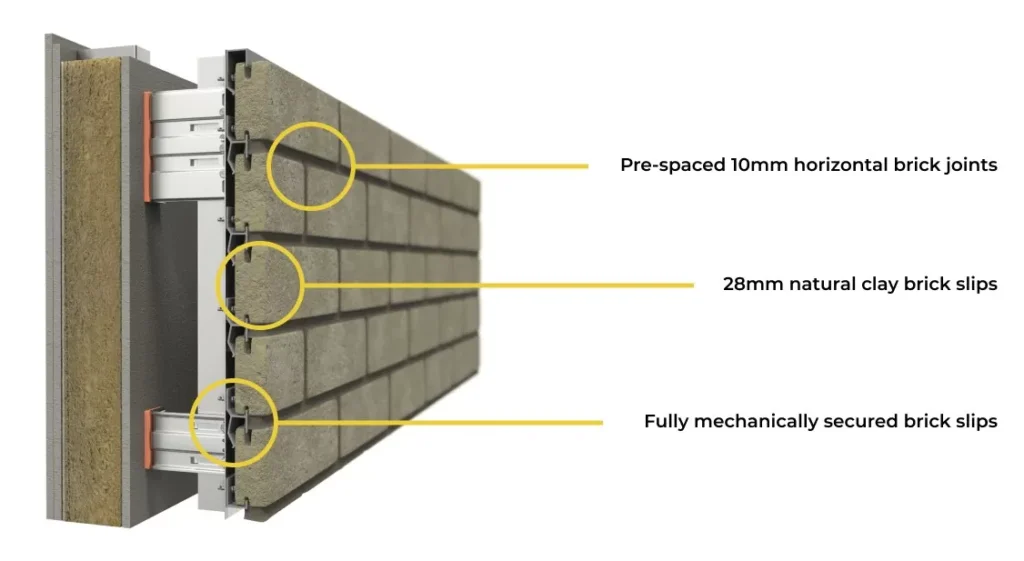

MechSlip embodies a streamlined, mechanically secured cladding solution that enhances authentic brickwork’s visual allure and durability. It offers cost savings for projects where traditional construction methods pose challenges. The system features 28mm thick Ibstock brick slips and anodised 6063T6 grade aluminium support rails. With an extensive range of colours, textures, and brick sizes, MechSlip provides all the advantages of rain-screen cladding, including reduced installation time and associated costs. Furthermore, MechSlip ensures a stunning authentic brick finish that guarantees long-term durability.

Experience the innovation of fully mechanically secured brick slips with our cutting-edge system. We prioritise safety by utilising non-combustible components, giving you peace of mind and compliance with regulations.

Our system offers versatile brick detailing options, allowing you to customise your project with precision and creativity. Whether you prefer a traditional or contemporary look, our brick slips provide the perfect solution.

Say goodbye to weather-related delays. Our installation process is non-weather dependent, ensuring efficient progress regardless of the conditions. You can rely on a smooth, uninterrupted workflow, saving time and resources.

Discover the benefits of our unique system today and unlock a world of possibilities for your architectural projects.

Key Benefits of MechSlip

More than just a perfect finish

MechSlip provides the aesthetic appeal of genuine clay brick with the added benefits of a lightweight, mechanically fixed system. It surpasses the Centre for Window and Cladding Technology (CWCT) ‘s rigorous testing standards. By eliminating weather dependencies, MechSlip offers design flexibility without compromising the choice of brick finish.

Key Features

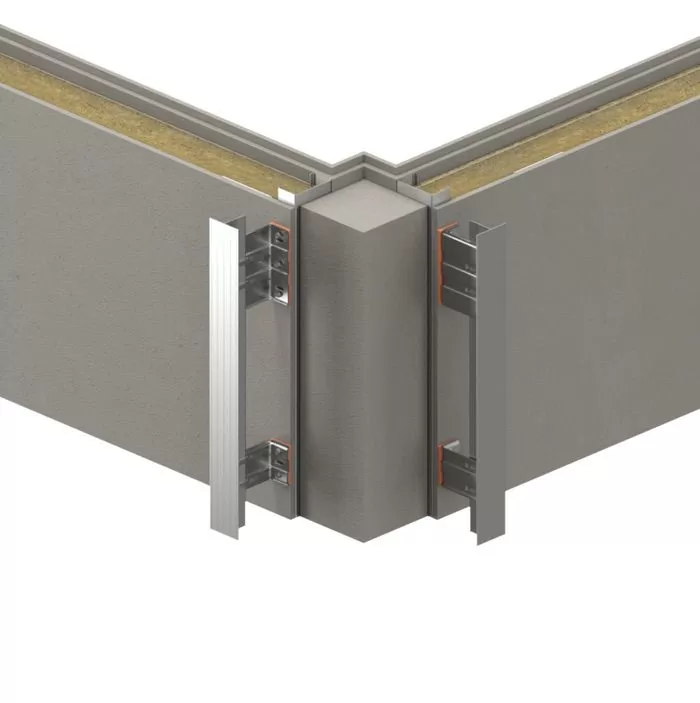

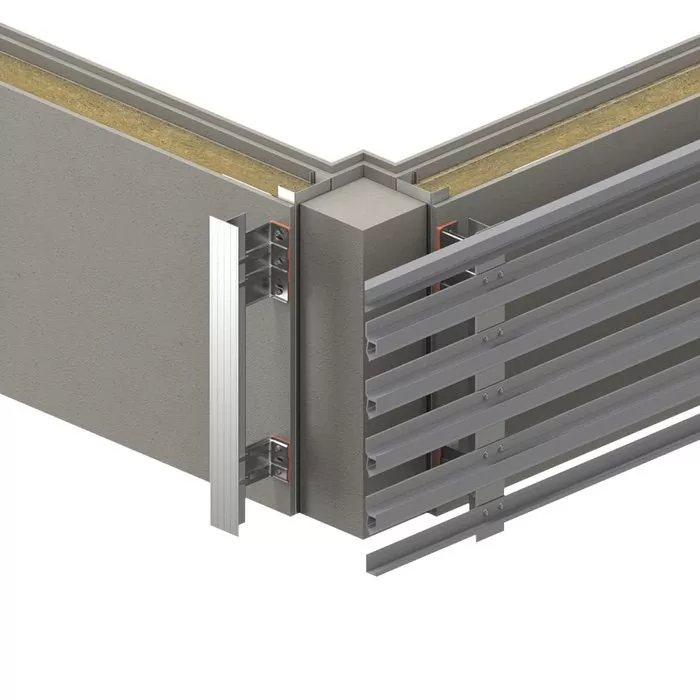

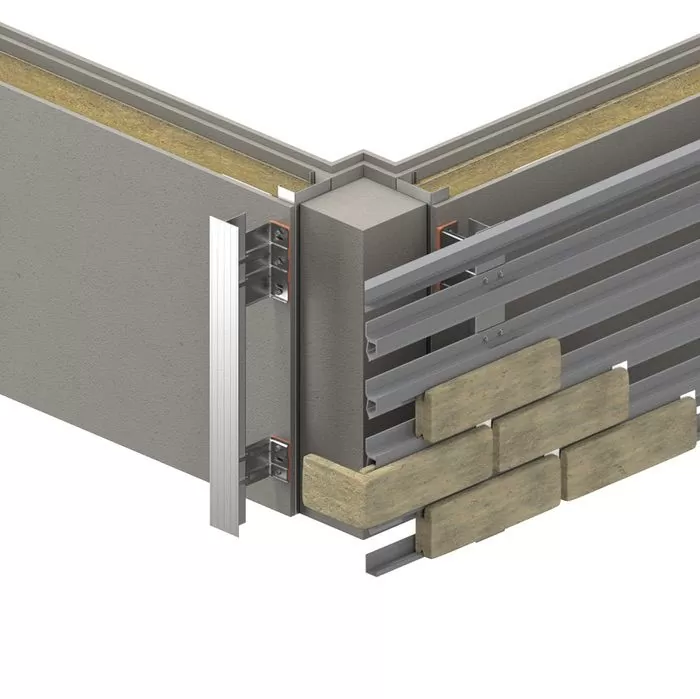

Brick System Components

Soldier bricks

Corner bricks

Stretcher and Header bricks

Complete Control with Simple Components

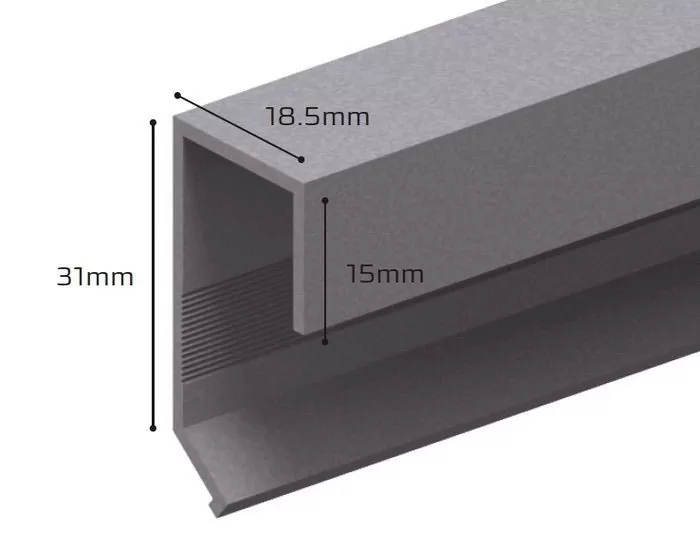

The full range of benefits MechSlip offers is attained through implementing specialised elements, encompassing a commencement, central, and upper rail system. These components are extruded using rugged, lightweight 6063T6 grade aluminium and anodised for increased durability. Paired with authentic clay veneer and corner brick tiles, these seamlessly blend into Ash & Lacy’s ground-breaking AxiAL rainscreen support systems for cohesive integration. The entire design and installation process is made uncomplicated from concept to completion.

Mechanical System Components

Starter

Brick spacer

Middle

Top

Six Simple Steps for Easy Installation

Working with MechSlip provides advantages from the start. The lightweight construction reduces demands on foundations and associated construction costs. The system is compatible with various building substrates, making it suitable for enhancing concrete, steel frames, masonry, and insulated panels. The installation process is efficient, straightforward, and budget-friendly, providing time-saving benefits compared to conventional bricklaying methods, all while preserving its visual allure.

STEP 1 – Secure NaturAL-X Vertical Support Rails

To begin the installation, securely attach brackets and vertical support rails to the building substructure. These should be fixed at a maximum of 600mm centres to ensure stability.

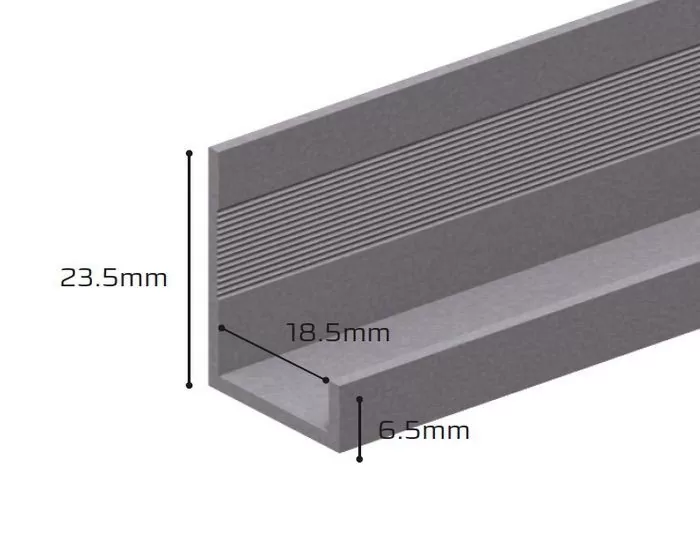

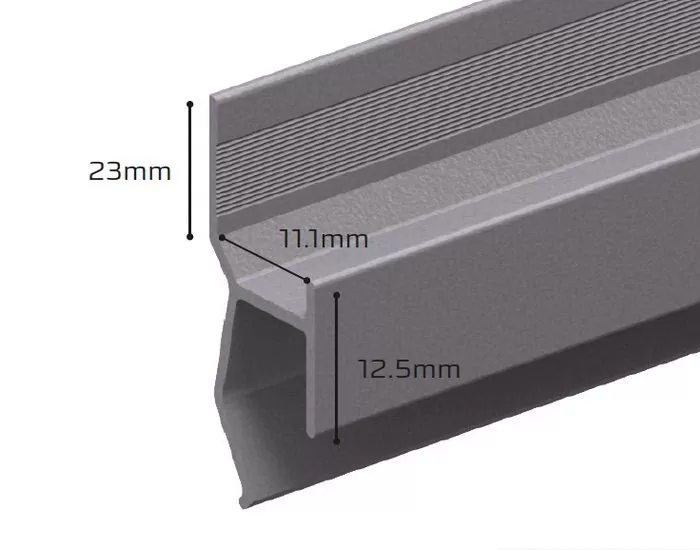

STEP 2: Install Middle Rails and Starter/Top Rail

Next, horizontally affix middle rails to the vertical supports at 75mm increments. Ensure to include a starter rail at the bottom and a top rail in their respective locations. The gauge tool can fix multiple rail courses simultaneously, ensuring accuracy and efficiency.

STEP 3: Place MechSlip Brick Tiles

Carefully slip MechSlip brick tiles firmly into place between the rails. Use the preformed upper and lower retainers as guides to ensure proper alignment and positioning.

STEP 4: Repeat the Process and Use Brick Spacers

Continue the process for the remaining bricks, ensuring a metal brick spacer is installed in the vertical joints between each brick. This action helps maintain consistent spacing and alignment throughout the cladding.

Step 5: Finishing Touches

The brick spacer automatically creates a 10mm wide vertical joint between bricks, while the upstand of the rail profile creates a 10mm horizontal joint (bed).

STEP 6: Finishing Touches with Parex Historic Mortar

Once the installation is complete, the joints between the bricks can be injection pointed with Parex Historic mortar. This step adds to the authentic and aesthetic appeal of achieving a classic clay brick finish.

Installation Video

Unleash your creativity with Mechslip

The MechSlip system offers an extensive range of over 300 natural brick colours, textures, and finishes. We are opening up a world of creative possibilities for architects and designers. Whether you prefer stock, handmade, wirecut, linear, or glazed bricks, MechSlip has options to suit your unique vision.

Brick Types

Handmade and Stock

Commonly has soft edges.

Stock

Handmade

Wirecut

Precise edges are formed within the manufacturing process although a softer edge can be achieved by rumbling.

Handmade

Brick Finishes

Stock

Sanded

Glazed

Dogfaced

Distressed

Creased

Popular Bricks

Available in 65mm and 73mm. More than 300 types available.

Glazed Bricks

Available in 65mm and 73mm. Colour can be matched

to client’s specifications.

Linear Blocks

Length available in 290mm, 327mm and 440mm. 40 types available

Materials

Fired clay brick slips supported by anodised aluminium rails affixed to steel

Test Programme

The test programme was carried out with results as follows:

Wind Resistance – serviceability & safety CWCT testing achieved ±2400 Pascals serviceability, ±3600 Pascals safety. PASS

Water Tightness – dynamic pressure CWCT testing achieved 600 Pascals – PASS

Impact Resistance Soft and hard body impact tests – CWCT testing achieved Class 1 serviceability, negligible risk safety. PASS.

Weatherability Tests – Hygrothermal testing to ETAG 034. PASS

Freeze/Thaw Resistance Freeze Thaw testing by ETAG 017. An additional freeze/thaw resistance test is carried out by the European method DD CEN/TS EN772-22, which involves subjecting a panel of brickwork to repeated freeze/ thaw cycles designed to simulate naturally occurring conditions. From the results, the bricks were classified as F2, i.e. suitable for use in states of severe exposure, in accordance with BS EN771-1, Specification for Clay Masonry Units.