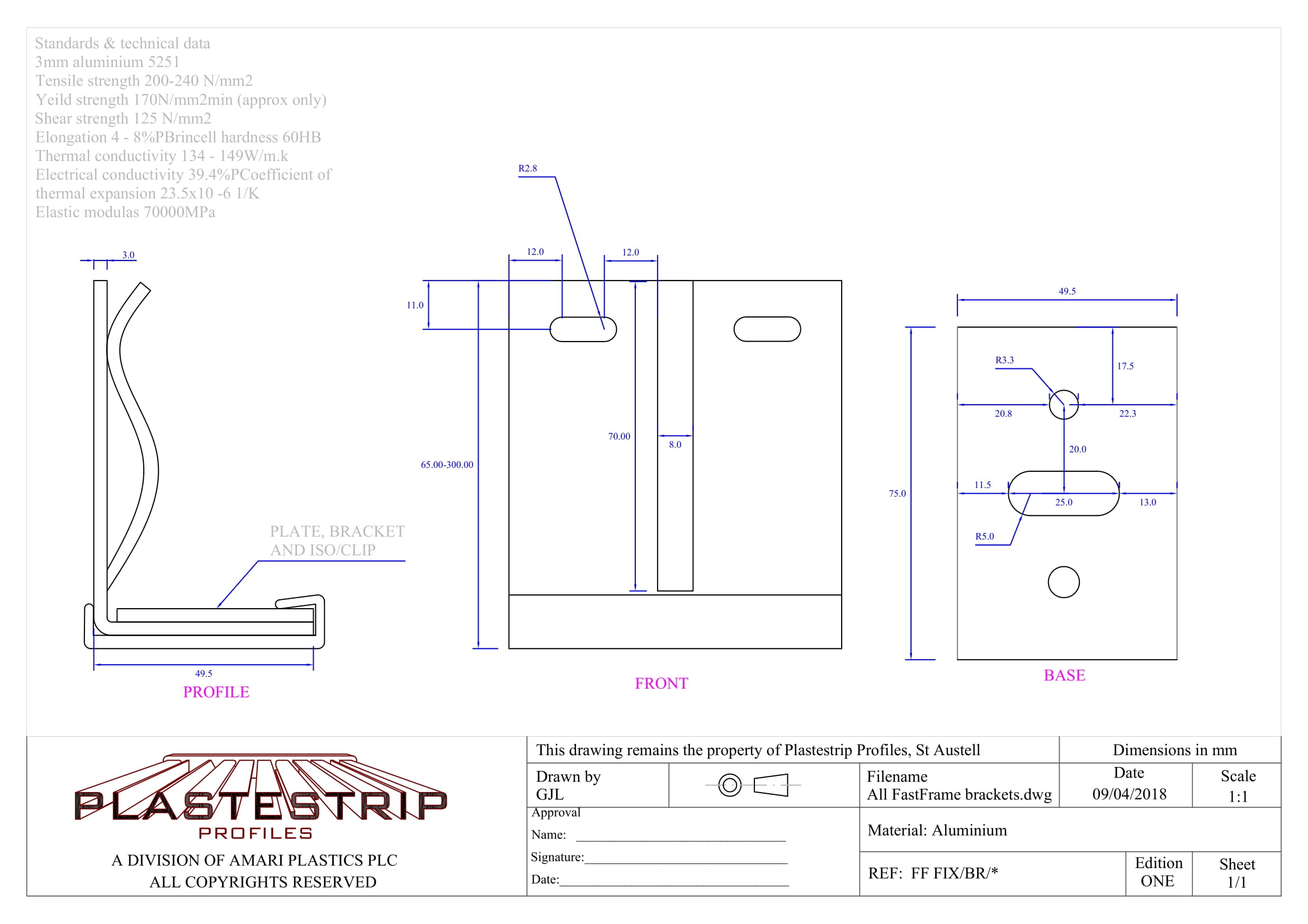

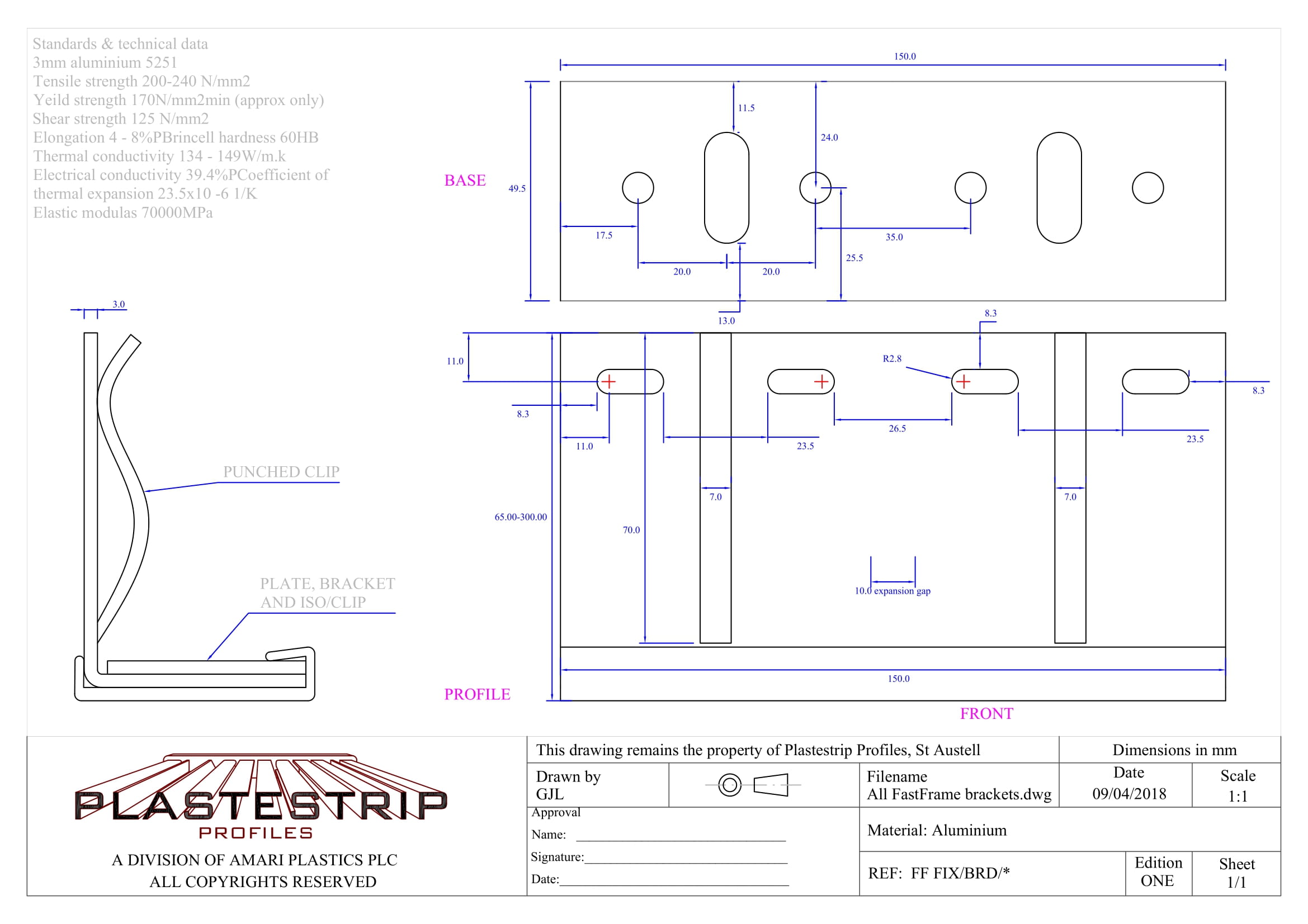

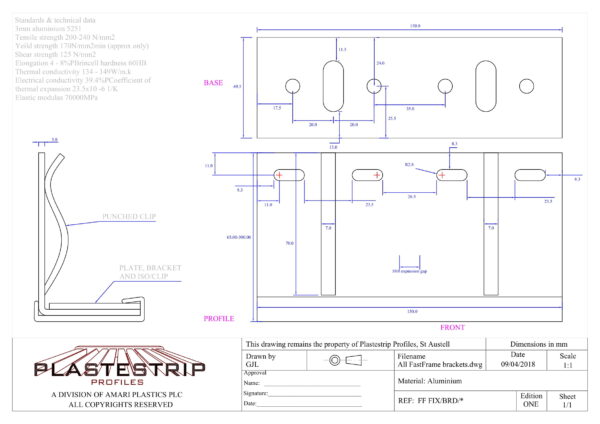

| Bracket size | Single bracket reference | Double bracket reference | XL double bracket reference | Potential cavity |

|---|---|---|---|---|

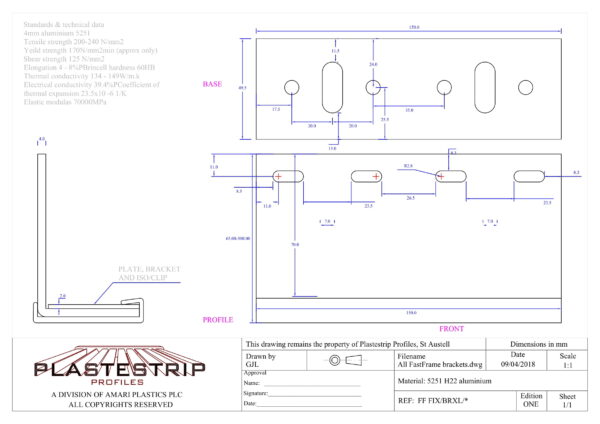

| 40 | FF FIX/BR/40* No helping hand punched into the bracket due to leg size |

FF FIX/BRD/40* | FF FIX/BRD/XL/40* | 50 – 63mm (with 40mm leg rail) 68 – 80mm (with 60mm leg rail) |

| 50 | FF FIX/BR/50* No helping hand punched into the bracket due to leg size |

FF FIX/BRD/50* | FF FIX/BRD/XL/50* | 56 – 72mm (with 40mm leg rail) 68 – 90mm (with 60mm leg rail) |

| 65 | FF FIX/BR/65 | FF FIX/BRD/65 | FF FIX/BRD/XL/65 | 71 – 88mm (with 40mm leg rail) 80 – 105mm (with 60mm leg rail) |

| 80 | FF FIX/BR/80 | FF FIX/BRD/80 | FF FIX/BRD/XL/80 | 88 – 120mm |

| 100 | FF FIX/BR/100 | FF FIX/BRD/100 | FF FIX/BRD/XL/100 | 108 – 140mm |

| 120 | FF FIX/BR/120 | FF FIX/BRD/120 | FF FIX/BRD/XL/120 | 128 – 160mm |

| 140 | FF FIX/BR/140 | FF FIX/BRD/140 | FF FIX/BRD/XL/140 | 148 – 180mm |

| 160 | FF FIX/BR/160 | FF FIX/BRD/160 | FF FIX/BRD/XL/160 | 168 – 200mm |

| 180 | FF FIX/BR/180 | FF FIX/BRD/180 | FF FIX/BRD/XL/180 | 188 – 220mm |

| 200 | FF FIX/BR/200 | FF FIX/BRD/200 | FF FIX/BRD/XL/200 | 208 – 240mm |

| 220 | FF FIX/BR/220 | FF FIX/BRD/220 | FF FIX/BRD/XL/220 | 228 – 260mm |

| 240 | FF FIX/BR/240 | FF FIX/BRD/240 | FF FIX/BRD/XL/240 | 248 – 280mm |

| 260 | FF FIX/BR/260 | FF FIX/BRD/260 | FF FIX/BRD/XL/260 | 268 – 300mm |

| 280 | FF FIX/BR/280 | FF FIX/BRD/280 | FF FIX/BRD/XL/280 | 288 – 320mm |

| 300 | FF FIX/BR/300 | FF FIX/BRD/300 | FF FIX/BRD/XL/300 | 308 – 340mm |

| 320 | FF FIX/BR/320 | FF FIX/BRD/320 | FF FIX/BRD/XL/320 | 328 – 360mm |

| 340 | FF FIX/BR/340 | FF FIX/BRD/340 | FF FIX/BRD/XL/340 | 348 – 380mm |

| 360 | FF FIX/BR/360 | FF FIX/BRD/360 | FF FIX/BRD/XL/360 | 368 – 400mm |

| 380 | FF FIX/BR/380 | FF FIX/BRD/380 | FF FIX/BRD/XL/380 | 388 – 420mm |